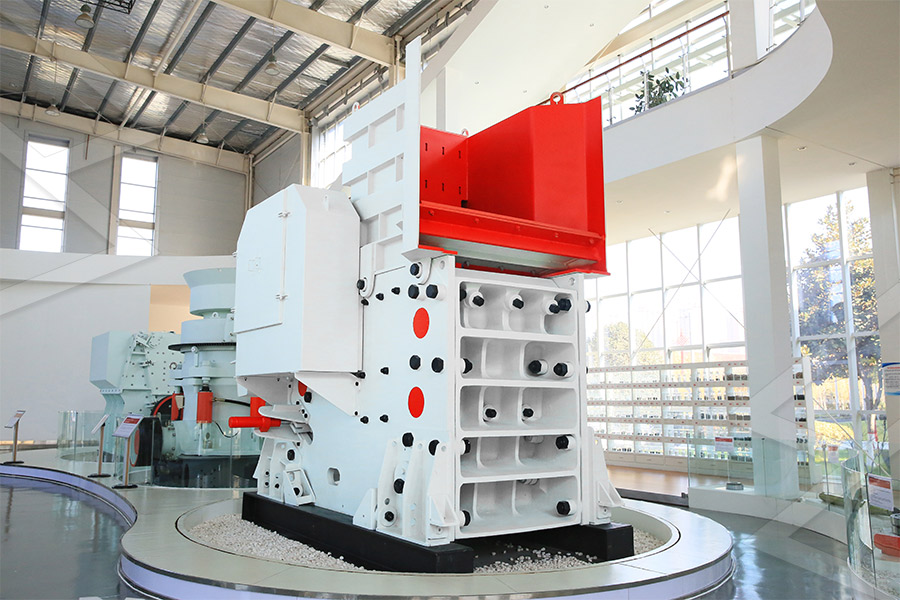

Large Production Granite Stone Crushing Machine Granite Impact Crusher

6 Granite Crushers for Efficient Granite Rock Crushing

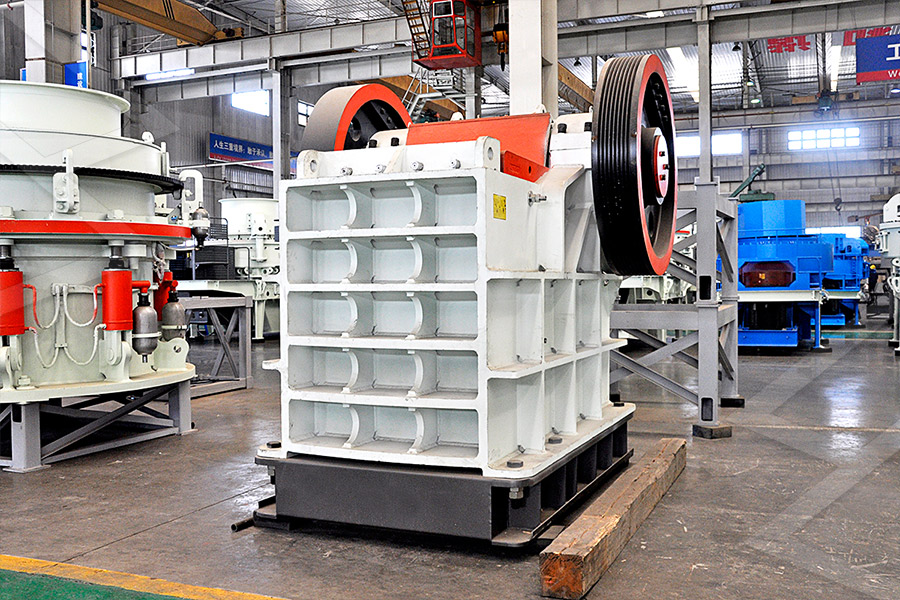

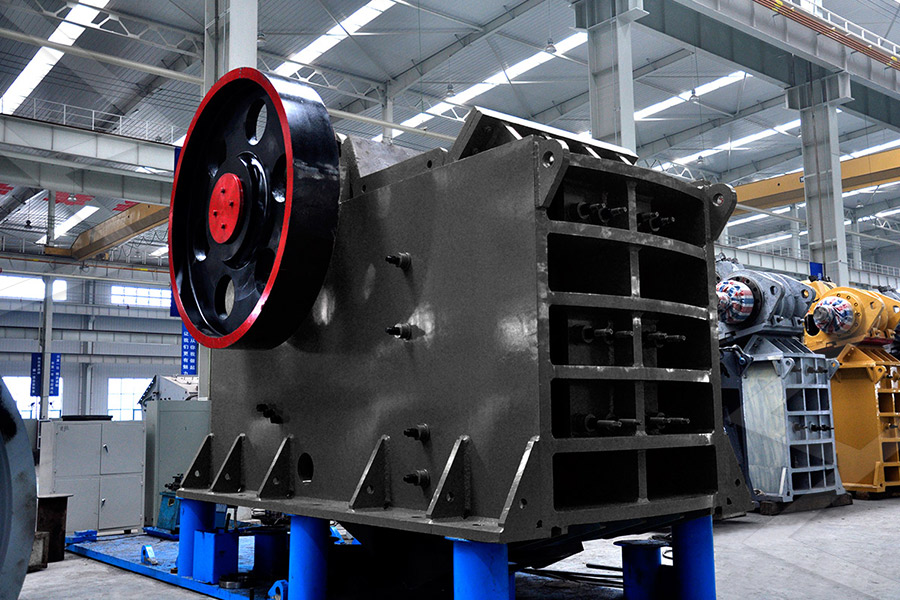

Due to the large feeding inlet and strong crushing capacity,jaw crushers can crush bulky granite rocks (above 450mm) into smaller sizes It is an efficient primary granite crusher The fine crushing jaw crusher developed by Ftmmachinery can carry out fine crushing of granite stones 展开Stedman delivers highperforming, lowmaintenance pulverizers crushers ideal for largescale grinding and milling grain and corn to supply distilleriesSecondary Impact Crushers Stone Granite 2024年11月8日 Large Construction 00500t/H Limestone Granite Pebble Crushing Machine Impact Crusher, Find Details and Price about Impact Crusher Impact Crusher Machine from Large Construction 00500t/H Limestone Granite Pebble Crushing Machine 2024年11月7日 High Production Capacity Limestone Granite Clay Mobile Impact Crusher Portable Stone Crusher Integrated Stone Crushing Plant US$25,0000079,99900 / Set 1 Set High Production Capacity Limestone Granite Clay Mobile Impact Crusher

.jpg)

granite stone crushing machine imapct crusher, impact stone crushing

We manufacture and supply granite stone crushing machine imapct crusher, impact stone crushing machine at a factory competitive price with features: granite crushing machine, Here I will introduce to you two types of AIMIX granite jaw crushers, APJE and APJV The granite jaw crusher is very suitable for primary crushing, among which the APJE adopts a Granite Crusher Machine High Efficiency And Good In 2024年11月7日 Granite stone crushing machine can be divided into three categories according to the feed and product particle size: Coarse crusher: from 1500~500mm to 350~100mm; 5 Granite Stone Crushers: Which is Best for Granite Crushing?2024年9月14日 Granite crusher is the stone crushing machine used for crushing granite rocks into small particles for building aggregates production and crushed fine granite for sand Granite Crusher LIMING(Shanghai) lmzgchina

.jpg)

Large Capacity Impact Crusher Fine Crushing Stone Breaker Granite

2024年8月18日 Large Capacity Impact Crusher Fine Crushing Stone Breaker Granite Pebbles Limestone Breaking Line, Find Details and Price about Stone Impact Crusher Mining 2024年1月18日 As for the stone crusher machines used for granite crushing production line, they can be divided into the jaw crusher, impact crusher, and cone crusher How to Arrange Granite Crushing Production Line In granite stone quarrying and mining operation, crushing will be the first processing stage Jaw crusher can be applied in primary How Much does a Granite Stone Crusher Cost in Kenya? Zenith Crusher2019年11月4日 Jaw crushing should reduce the granularity of granite as much as possible, and the impact crusher will shape the crushing, so as to achieve the crushing effect of excellent particle size and appropriate control of low wear Granite Rock Crushing Flow Price JXSC 2024年10月14日 4 Hammer crusher A hammer crusher is a special type of crusher that consists of a rotor with disks on which the hammers are mounted and articulated in the outer area They, therefore, have a design similar to What Machines Do Stone Crushing Plants Need?

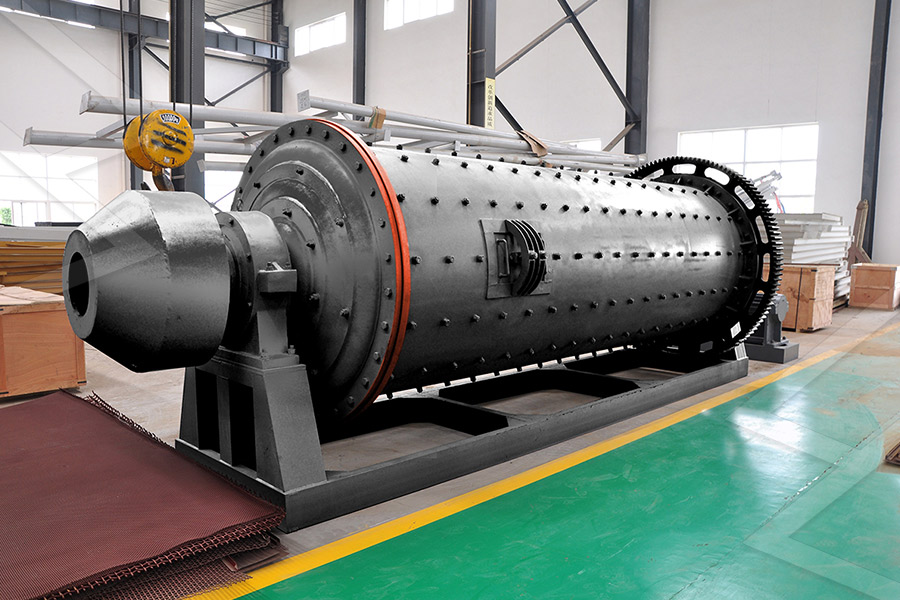

Granite Crusher Granite Stone Crushing Plant Mortar Plant

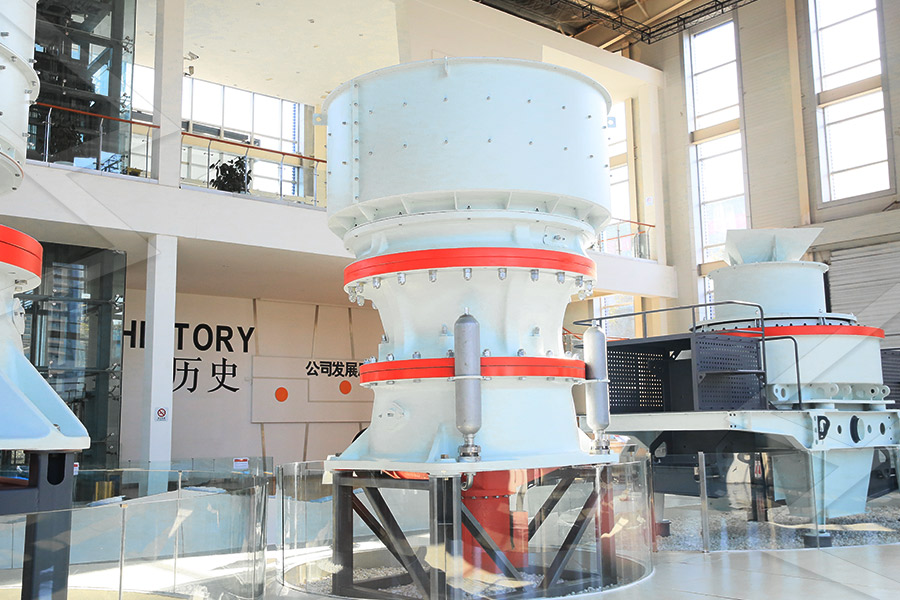

2021年12月1日 For the granite stone crushing plant with large output, the threestage crushing machine should be used as far as possible, the jaw crusher + fine jaw crusher/cone crusher + impact crusher can be adopted For granite crushers with low grain size requirements, a twostage jaw crusher can be adoptedThe quarry crusher for sale’s crushing ratio is large and the crushing strength is uniform AIMIX’s quarry impact crusher is the finely crushing equipment It has wide applications Moreover, this rock crusher quarry can crush all kinds of coarse, medium, and fine materials, such as limestone, feldspar, calcite, granite, talc, barite Quarry Crusher Maximize Efficiency and Productivity2023年2月22日 200t/h Pebble Crushing Mobile Production Line; 150t/h Granite Mobile Crushing Plant; 100t/h Slag Mobile Crushing Plant A primary gyratory crusher is used for the primary crushing of large stones It has a concave surface and a conical head, which provides a larger crushing surface than a jaw crusher such as mining, quarrying Different Types of Stone Crusher Machines AGICO2023年9月18日 Equipment included a jaw crusher, a cone crusher, and an impact sandmaking machine Production details: The jaw crusher has a deep crushing chamber, a large crushing mouth, strong processing capacity, and an hourly output of 451510 t/h The stones after the jaw crusher crushing go to the cone crusher for further crushingGranite Crushing And Screening Production Line Eastman Rock Crusher

.jpg)

5 Granite Stone Crushers: Which is Best for Granite Crushing?

2024年11月7日 The manufacturing process of jaw crusher is also relatively mature in China and abroad, so in the field of coarse crushing, jaw crusher is the most commonly used granite stone crushing machine Advantages: simple structure, reliable operation, light selfweight, cheap price, various models, small overall dimensions, large size of feed inlet (up 2023年2月28日 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications These plants find application in quarrying, mining, construction, and recycling operations Stone crusher plants consist of several components, including a primary crusher, secondary crusher, and vibrating Crushing it: A Comprehensive Guide to Stone Crusher PlantsDisadvantages: The cost is higher than that of the twostage jaw crusher solution (because granite is a relatively difficulttobreak material, the wearresistant parts of the impact crusher are relatively high in loss, and the production cost increased by longterm production is considerable)Granite Crushing Solution Eastman Rock CrusherTake Plan A as an example, the process of granite crushing using a cone crusher includes the following steps First, the blasted raw materials enter the jaw crusher from the vibrating feeder for the primary crushing The crushed stones are Granite Crushing Plant Granite Crusher For Sale

.jpg)

The Ultimate Guide on How to Crush Stone

Equipment for Crushing Stones Choosing the right equipment to crush rock is essential to maximize efficiency, minimize maintenance, and produce highquality crushed stones suitable for various applications Jaw Crushers: A jaw crusher is immensely powerful, making it ideal for crushing large, hard rocks like natural stone, granite, and basalt 5 天之前 What is quarry crusher? Quarry crusher is a piece of equipment that break down natural stone or other solid materials, such as limestone, granite, cobblestone, quartz, and basalt, into sand, aggregates or gravel that can be What Is Quarry Crusher Onsite Processing 3 天之前 Rock crusher Application: Quarry stone crushing: cobblestone, basalt, limestone, granite, talc, river Excellent in crushing largescale materials such as granite and basalt Symons cone crusher Capacity: 27 Impact Crusher Capacity: 30500t/h Feeding size: 700mm Application: Suitable for crushing medium hardness and low abrasive Stone Crusher│Ore Crushing Machine JXSC Machinery2024年10月23日 The JOYAL Impact Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone The Impact Crusher is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so onJoyalImpact Crusher,Impact Crusher For Sale,Impact Crusher

.jpg)

A Comprehensive Guide to Stone Crusher Machines AGICO

2023年2月22日 Stone crusher machines are essential tools in the construction industry, used to crush rocks and stones into smaller pieces for a variety of applications This guide provides an overview of stone crusher machines, including their history, components, applications, and buying considerations Whether you are a contractor, landscaper, or building owner, this guide will 2023年2月22日 When buying a stone crusher machine, there are several factors to consider, such as the type of stone to be crushed, the required crushing capacity, the power supply, and the budgetIt’s also important to choose a reliable supplier with a good reputation for quality and service Other factors to consider include the machine’s size and weight, ease of operation A Comprehensive Buying Guide for Stone Crusher MachinesAn allaround crusher control system keeps you crushing longer Straightforward crusher settings and reduced maintenance effort maximize your uptime Get More Clarity About Your Operation We make crushing as easy as using an app Operators know the condition of the machine and get the confidence to do it right Enjoy the Comfort and Safety of Granite Rock Crusher Mobile Jaw Impact CrushersGranite Crusher Machine Granite crusher machine is a powerful machine that crushes the granite mine, which is unprocessed in nature, into small pieces for use in certain areas Granite crusher machine is a facility called stone crushing and screening plant in order to use in the construction industry by crushing hard minerals such as graniteGranite Crusher Machine Stone Crushing and Screening

.jpg)

HighQuality Granite Crusher For Sale Customized

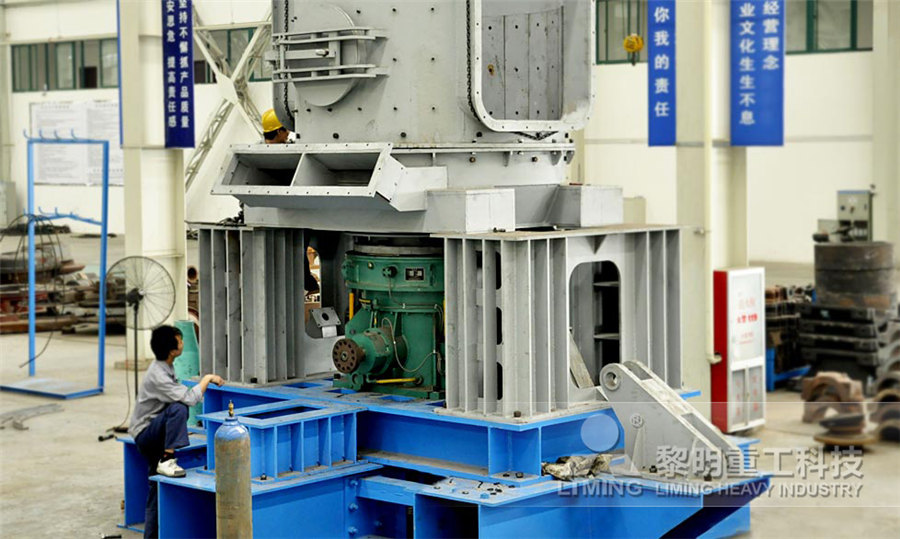

1 天前 Impacttype granite crusher Impact crusher uses the high speed rotating hammer head to collide with granite and produce impact force to crush granite The impact crusher has the advantages of high efficiency and low energy consumption It is suitable for crushing harder granite and can produce a better shape of the finished product Wearing partsA double roller coal crusher is a type of crushing machine that uses two cylindrical rollers to crush mater What is the use of CNC double roller crusher? CNC double roller crusher is a key equipment in modern sand and gravel rock crusher,stone crusher,double roll AGICO offers stone crushing equipment for sale at a competitive price Buy jaw crusher, impact crusher, cone crusher, hammer crusher, etc crushers of different specifications LF LargeDiameter Impact Crusher; CS5X Impact Crusher; Crushing Equipment Supplies Jaw Crusher, Secondly, granite crusher has a high crushing efficiency, which can save energy and reduce production costs Thirdly, granite crusher has a long service life and requires minimal maintenance, making it a costeffective solution for granite stone crushing In conclusion, granite crusher is an essential crushing machine in the granite stone Granite Crusher

.jpg)

Rock Crushers Pulverizers Williams Crusher

The Willpactor II® handles feed sizes beyond the range of conventional secondary crushing machines This secondary crusher features a large feed opening and a contoured hichrome rotor with easy maintenance and upkeep These features make the Willpactor II® impact crusher a great asset for any rock crushing application2024年10月17日 Granite Jaw Crusher Jaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10100 mm Jaw crusher has super wear resistance and impact resistance, very flexible adaptability, more safe and reliable operation process, ultra Granite Stone Crusher in NigeriaSBM Industrial Technology LF LargeDiameter Impact Crusher; CS5X Impact Crusher etc individual fixed crushers or the complete stone crushing production lines are all available Mobile crushing plant, screening equipment, vibrating feeders, sand making and washing machine, conveyor belt, and other machines needed in the stone crushing or professional sandstone line STONE CRUSHING WITH HIGH EFFICIENCY AND LOWER COST2024年7月19日 Hardness is a key factor in choosing the appropriate stone crusher, as different stones naturally have different hardness levels Hard stones, such as granite and basalt, usually require powerful jaw crushers and cone crushers for effective crushing The crushing process for some softer rocks is simpler, as they require less crushing forceHow to Crush Stones: A Comprehensive Guide Fote

Types of Rock Crushers Quarry Crushing Equipment Kemper

2 天之前 For instance, if the final size of your product only needs to be between 4 inches and 6 inches, a primary jaw or impact crusher can accomplish your goals However, you will likely require a much finer product, and that means incorporating up to three—or even four—stations with a variety of crusher types 1 Primary Crushing2024年1月24日 Primary Crushing: After transport to the processing site, the original granite blocks undergo primary crushing using large jaw crushers These machines break down the large rocks into smaller pieces Secondary Crushing: Subsequently, the smaller rock pieces are sent to secondary crushing equipment, such as cone crushers or impact crushers Introduction of granite crushing and screening production line2023年2月15日 LF LargeDiameter Impact Crusher; CS5X Impact Crusher; PF Impact Crusher; PFW Impact Crusher; The Blake jaw crusher is the most commonly used jaw crusher in the stone crushing industry It has a high crushing capacity, and it is easy to operate and maintain 200t/h Pebble Crushing Mobile Production Line; 150t/h Granite Mobile Crushing A Guide to Types of Jaw Crushers for Crushing Rocks and 2024年1月18日 As for the stone crusher machines used for granite crushing production line, they can be divided into the jaw crusher, impact crusher, and cone crusher How to Arrange Granite Crushing Production Line In granite stone quarrying and mining operation, crushing will be the first processing stage Jaw crusher can be applied in primary How Much does a Granite Stone Crusher Cost in Kenya? Zenith Crusher

Granite Rock Crushing Flow Price JXSC

2019年11月4日 Jaw crushing should reduce the granularity of granite as much as possible, and the impact crusher will shape the crushing, so as to achieve the crushing effect of excellent particle size and appropriate control of low wear 2024年10月14日 4 Hammer crusher A hammer crusher is a special type of crusher that consists of a rotor with disks on which the hammers are mounted and articulated in the outer area They, therefore, have a design similar to What Machines Do Stone Crushing Plants Need?2021年12月1日 For the granite stone crushing plant with large output, the threestage crushing machine should be used as far as possible, the jaw crusher + fine jaw crusher/cone crusher + impact crusher can be adopted For granite crushers with low grain size requirements, a twostage jaw crusher can be adoptedGranite Crusher Granite Stone Crushing Plant Mortar PlantThe quarry crusher for sale’s crushing ratio is large and the crushing strength is uniform AIMIX’s quarry impact crusher is the finely crushing equipment It has wide applications Moreover, this rock crusher quarry can crush all kinds of coarse, medium, and fine materials, such as limestone, feldspar, calcite, granite, talc, barite Quarry Crusher Maximize Efficiency and Productivity

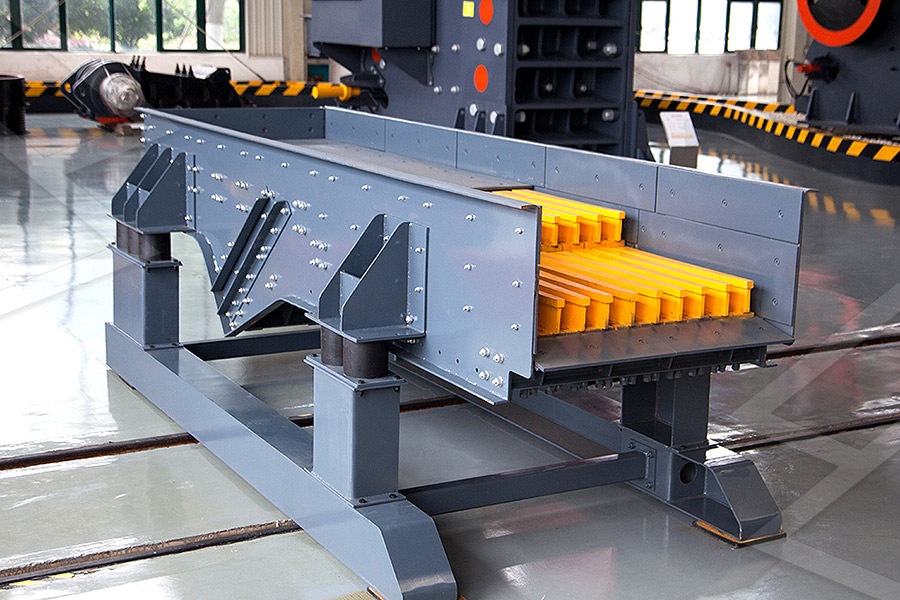

Different Types of Stone Crusher Machines AGICO

2023年2月22日 200t/h Pebble Crushing Mobile Production Line; 150t/h Granite Mobile Crushing Plant; 100t/h Slag Mobile Crushing Plant A primary gyratory crusher is used for the primary crushing of large stones It has a concave surface and a conical head, which provides a larger crushing surface than a jaw crusher such as mining, quarrying 2023年9月18日 Equipment included a jaw crusher, a cone crusher, and an impact sandmaking machine Production details: The jaw crusher has a deep crushing chamber, a large crushing mouth, strong processing capacity, and an hourly output of 451510 t/h The stones after the jaw crusher crushing go to the cone crusher for further crushingGranite Crushing And Screening Production Line Eastman Rock Crusher2024年11月7日 The manufacturing process of jaw crusher is also relatively mature in China and abroad, so in the field of coarse crushing, jaw crusher is the most commonly used granite stone crushing machine Advantages: simple structure, reliable operation, light selfweight, cheap price, various models, small overall dimensions, large size of feed inlet (up 5 Granite Stone Crushers: Which is Best for Granite Crushing?2023年2月28日 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications These plants find application in quarrying, mining, construction, and recycling operations Stone crusher plants consist of several components, including a primary crusher, secondary crusher, and vibrating Crushing it: A Comprehensive Guide to Stone Crusher Plants

Granite Crushing Solution Eastman Rock Crusher

Disadvantages: The cost is higher than that of the twostage jaw crusher solution (because granite is a relatively difficulttobreak material, the wearresistant parts of the impact crusher are relatively high in loss, and the production cost increased by longterm production is considerable)